Chapter 20.3 - The Blower; Regulator Bellows

The principles of gusseted bellows making are dealt with at greater extent in a MMD Technical Paper here. This medium sized bellows is hinged outside with Leather Supply House Item DC1, 2.5-3 oz. deer skin. and inside with muslin. First, the four stiffened bellows sides are prepared. Cut strips of these materials, and using masking tape, apply the leather to the outside folds with hot glue. For the center fold, the two smaller edges of the ribs are placed together, touching each other.

Then, fold the assembly closed, and glue on the inner layer of muslin. When gluing any fold, the side on the inside of the fold angle is glued on first, with the fold open. Then the fold is closed, and the outside of the angle is glued. If it is not done in this order, the hinge will bind. Here is the advantage of using hot glue. It gels in a few seconds, and holds the leather with Craig Brougher's "death grip", even before it is fully dried. By working around, one step at a time on each of the four sides, the grip on the last step is fully established by the time you get around to the next step. You can work right along, without waiting for anything to dry.

Then apply strips of muslin on the outer edges of the inner side. These are glued to the wood only, not to the inside of the leather strip that is already there.

Trim the leather and muslin strips. To prepare to attach the bellows sides, fold the assemblies; lay them on the lower chest, and put the lid down on them. It is important to attach stiffened bellows sides with them fully closed, for two reasons. First, this prevents binding of the hinges. Just as important, this assures that the sides always lay flat when the bellows closes. Little wooden blocks make sure that these are indeed level. If this is not done, the angles will end up unequal, and the inner edges of the sides may hit the lid or the bottom, and make a noise.

Working your way around the box, first glue the inner muslin strip to the edges of the box and the lid. Pull the cloth very tight, so that the edges of the ribs come right up to the edges of the wood. Then, go around again, and glue on the leather layer the same way. Masking tape defines the lower trim line where the bottom folds lap over the sides of the box.

Now, to make ready for the corner gussets, prop the bellows open. The normal maximum opening is conventionally designated to be with the fold angle at 90 degrees, or the ribs at a 45 degree angle. So, to allow a bit of play in the leather gusset, prop up the lid a bit more than 90 degrees. The gussets are rectangles of leather, which are surprisingly hard to measure. The easiest way for me is to use a strip of tape placed along the longest, inner edge, to get the length of the piece; and another tape around the gap, to get the width.

Using these tapes, cut out the leather piece. The center part of the gusset, where it goes around the center folds, has to be "longer" than the rest of the leather, so it will fit around the corner. The edges of the piece must be stretched. Only leather does this; that is why people still use only leather here, instead of some cheaper, modern material. To do this, pull the centers of the sides of the leather rectangle across the sharp edge of the table very firmly, several times.

The leather is first glued only the inner fold area, on both sides. Some stretchy PVC electrical tape holds the leather tightly into the folds, while it gels. A bit of masking tape holds the free end out of the way. This center joint is the one that must be very firmly set before proceeding further. One has to pull the leather very hard, to stretch the remaining corners around the lid and box. So take a break here.

Trim off any rough spots, and make a smooth, rounded corner of the wood. Apply hot glue to one side of one of the eight remaining areas to be closed.

Pull down the corner of the leather very firmly. Make sure the leather sticks to the entire area of the wood, right up to the edges of underlying layer of leather. Quickly glue the opposite side of this opening, and pull the other corner down. Both ends have to be tugged down and toward the center of the bellows, very firmly, to stretch the leather smoothly around the corner. Repeat eight times.

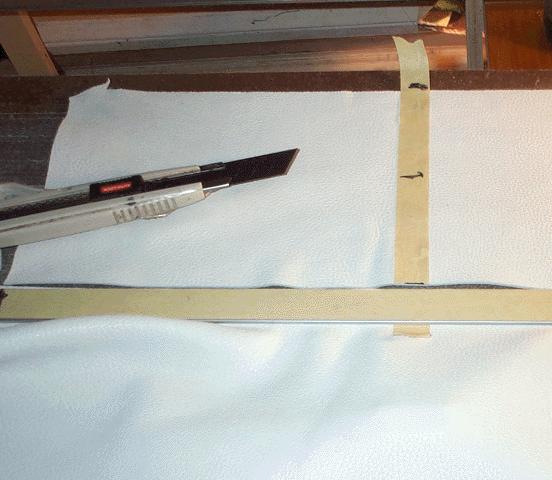

A metal straight edge is nailed to the box, along the line of the masking tape. Then the leather is cut along the straightedge, and the excess leather and masking tape is pulled off, leaving a neat edge.