Chapter 2.2 - Preparing the Stop Action Side Chests

After the chests are disassembled and cleaned, mask and reshellac them. This is not done for looks, but to refresh the existing shellac which may have developed cracks over the years. Wood is porous, and shellac was used originally to seal it.

The ends of the chests were covered with bellows cloth, to seal the joints between wood running in different grain directions. replace this with hot glue; then trim the edges with a bastard file (much neater than a knife, the way it was done on player pianos). Them mask and seal the edges of the cloth with "Goopalac". Thick, dark brown shellac made by mixing equal volumes of Behlan's raw shellac flakes and alcohol in a coffee can. This stuff will be used throughout the project, just as it was used by the people who originally made players. Shellac that thick won't keep; that's why you must make it yourself.

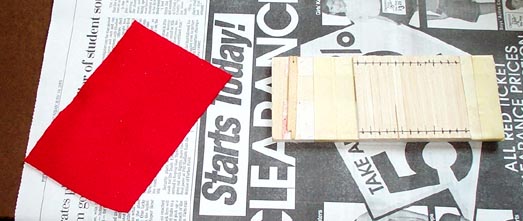

When the stop pallets are opened, their rear ends rest on little strips of felt. Throughout the organ, such strips were used, and to avoid getting glue on the pallet seating area, they were made up ahead of time, on thin wooden sticks nailed to the valve boards. The ones in the stop chests were moth eaten, and wouldn't come off without breaking the sticks. So I made new ones: cut little sticks, 1/4" x 1/16", longer than needed. Stick them to a scrap wood with the micro-carpenter's friend, double faced carpet tape. Saw the whole board to make the all sticks the correct length all at once, and drill little holes for the nails. Glue new felt to the whole thing. When dry, trim and cut them apart like pallets, and renail them inside the chest.

The rear guide rods for the pallet actuators go through bushed holes at the rear of the chest. These bushings were physically intact, but some prior owner didn't understand how things could be made to work, so he greased the bushings with something that dried up and corroded the rods. So I had to pull new bushings. These have to be trimmed quite flat to the inner side of the chest, because a leather valve seat seals around the hole when the stop is closed, and this area must be very flat.