Tonnesen Music Roll Perforator & Reader

Music Roll Reader &

Perforator

Custom Music Rolls, Richardson

TX

by Richard

Tonnesen (990508 MMDigest)

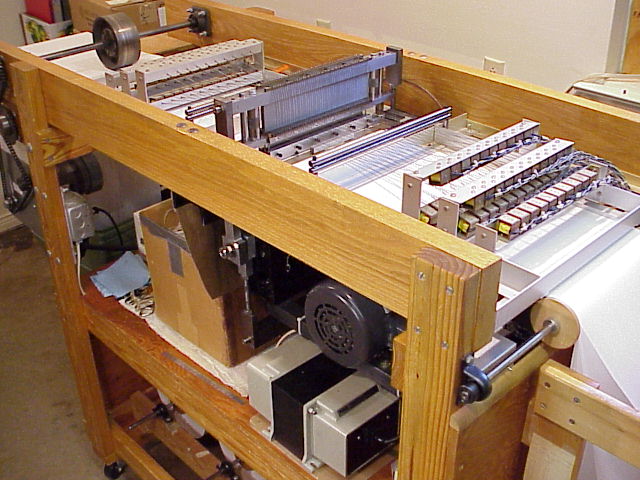

The reader and punch were completed in 1979 and were operated by an

Interdata 7/16 minicomputer that had 16K of core memory. Now, the

real time control programs run on a single board computer located in the

reader and punch electronic package. The real time computer gets

or sends roll data to the master reader or punch program running on a Macintosh.

Richard Tonnesen <rtonnesen@attbi.com>

Custom Music Rolls

903 Sandalwood Ave.

Richardson, TX 75080 USA

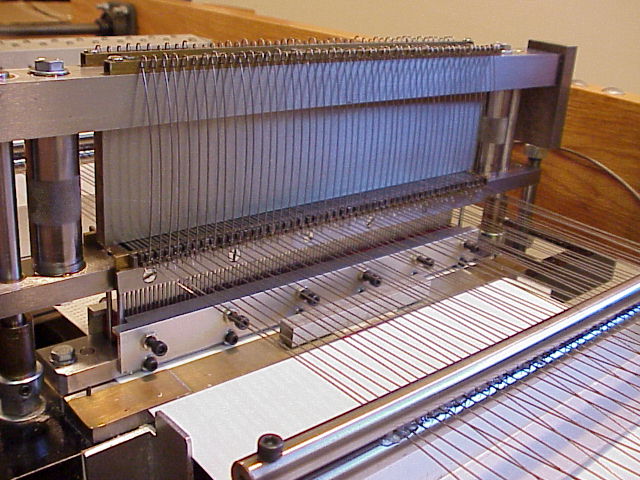

Figure 1. The music roll in the transcribing assembly is moved

by rotating identical capstans above and below the tracker bar. The

paper wraps about one-quarter turn around each rubber-coated capstan; a

pressure roller is not used. 100 hoses from the brass tracker bar

connect to vacuum operated pneumatic pouches which operate tiny wire switch

contacts. A rotating shutter connected to the paper drive system

interrupts a light beam at each 0.022 inch of paper travel. This

signal causes the electronic commutator circuit to read the state of the

pouch switches. The transcriber system has been in continuous use

since 1979, and it requires no more maintenance than a well-maintained

player piano. |

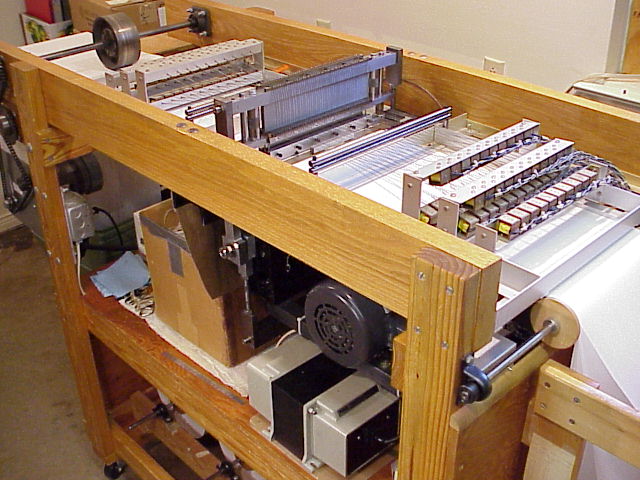

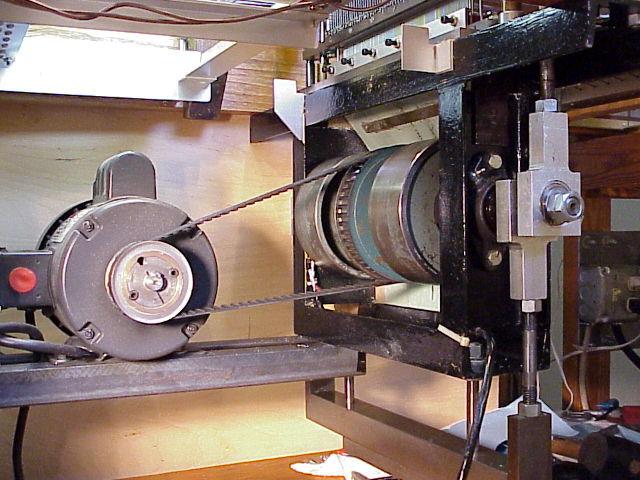

Figure 2. The perforator assembly. A bank of 50 solenoids

is at each side of the punch assembly. The end of the main crankshaft

can been seen to the left of the main drive motor. Below the motor

is the isolation transformer. I had to add it to keep the motor starting

transient from crashing the computer in the punch. Five or six sheets

of paper are pulled by two crown-faced iron pulleys which are held

against the paper (and each other) by two screws that mash the bottom pulley

against the top one. The 3/4-inch pulley shafts become slightly bowed

from the force! Since the paper advance per step is small (.022 inch)

it is not necessary to stop the capstan drive while punching -- the paper

simply stretches slightly. |

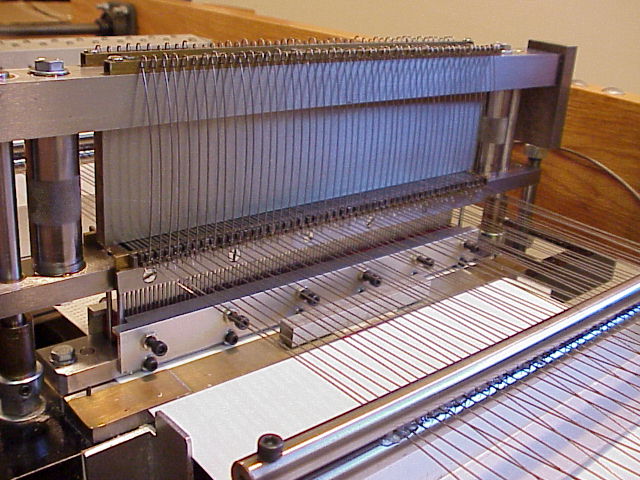

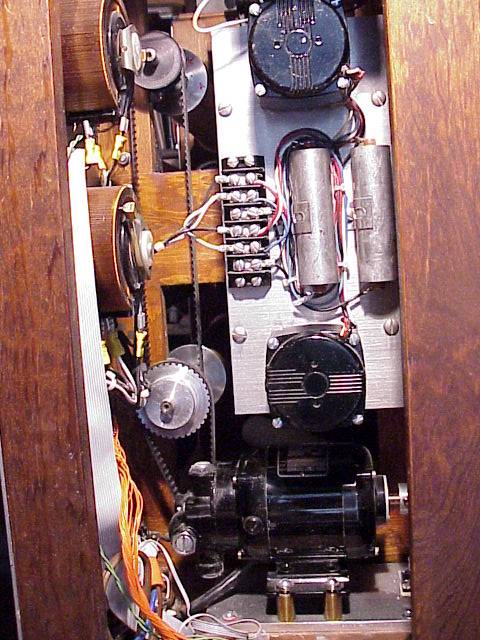

Figure 3a. The punch assembly. Wires from the solenoids

pull the interposers into the gap between the punches and the oscillating

ram. The vertical wires are return springs. |

Figure 3b. Close-up of the punch assembly, showing the pull wires

alternating with the return springs. |

Figure 4. Interposer bar detail. The interposer bar is

shown with centering spring on the left and pull wire on the right.

The bar at the top of the interposer bar represents the punch ram that

pushes the interposer bars and punches down on the down stroke of the punch

cycle. The notch in the interposer is aligned with the head of the

punch as it normally is at the start of a non-punching down stroke.

The punch head slips up into the notch on the down stroke, and therefore

does not get pushed down far enough to penetrate the paper. To punch

a hole, the interposer bar is pulled to the right so that the solid part

of the bar is over the punch head. This forces the punch down and

through the paper on the down stroke. On the up stroke, the whole

interposer assembly is lifted. This causes the punch heads to seat

in a recess in the interposer support bar. This allows the solenoids

or the return springs to move the interposer without having the bar catch

on the punch head as it moves to its new position. |

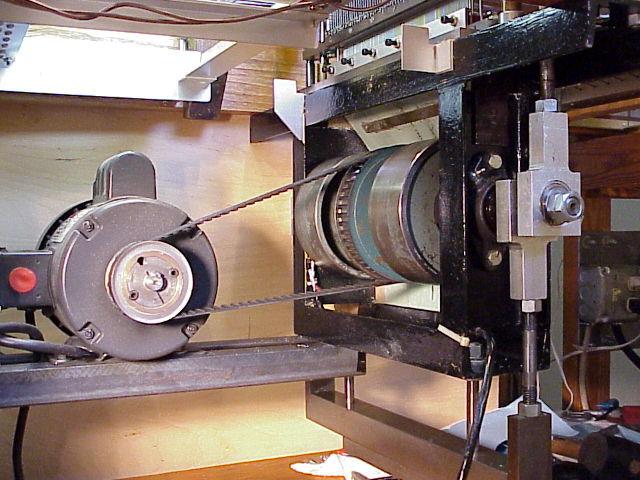

Figure 5. This picture shows the perforator drive motor and the

main crankshaft, with flat face iron pulleys for flywheels. The square

counterweight bar at the bottom, below the crankshaft, weighs the same

as the punch ram in the upper assembly. The counterweight is moved

the same distance as the ram on each rotation of the crankshaft, but it

is 180 degrees out of phase to cancel the vibration. The main shaft

turns at fifteen revolutions per second. |

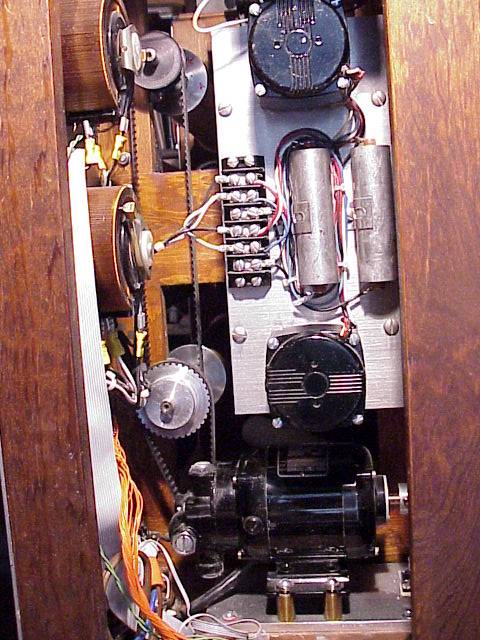

Figure 6. Reader paper drive. This photograph is taken looking

in the right side of the reader. Two AC torque motors are mounted

on an aluminum plate. Both apply torque to turn clockwise as seen

from this end. The upper motor has a low voltage applied, and supplies

pay-out tension to the supply spool as it unwinds against the torque.

The lower motor turns the take-up spool clockwise. It is operated

at nearly maximum torque because it drives a much larger diameter spool.

Driving this spool clockwise increases the angle of wrap around the lower

capstan roller, and provides an increasing angle of wrap as the take-up

spool gets full during the reading process. This helps prevent paper

slipping on the capstan. The variable transformers to the left provide

power to the torque motors. The paper is pulled by the capstan rollers.

These are driven by the variable speed DC motor at the bottom. It

drives the lower capstan by a toothed belt. That capstan drives the

upper capstan via a second toothed belt and equal sized pulleys. |

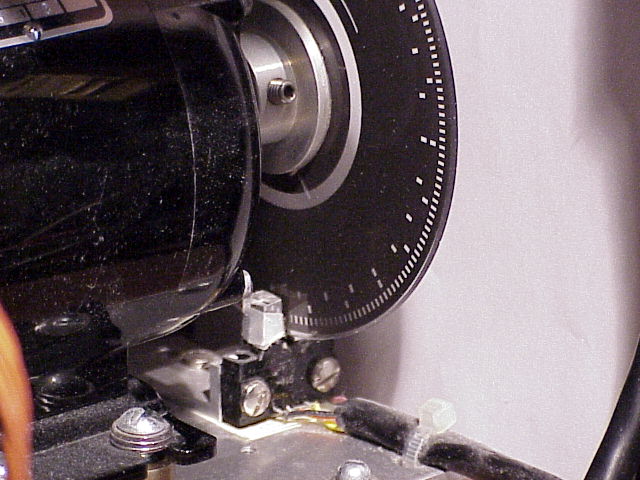

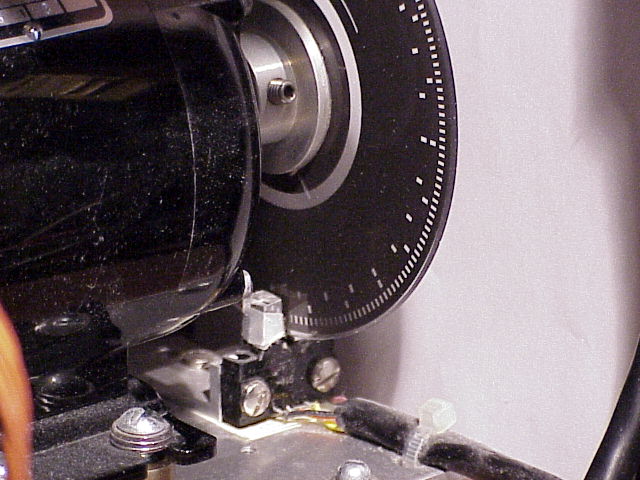

Figure 7. Paper Motion Clock. This close up of the variable speed

DC motor shows an optical disk attached to the end of the armature shaft.

This disk interrupts the light passing between the arms of the sensor mounted

at the bottom. This sensor generates corresponding electronic pulses

which are related to the paper motion. The pulses control the sampling

of the reader contacts so that the sampling distance is equal to the step

advance on the punch. Thus the paper may be driven at any speed or

be stopped and restarted, and still be sampled at exactly the selected

spacing. |

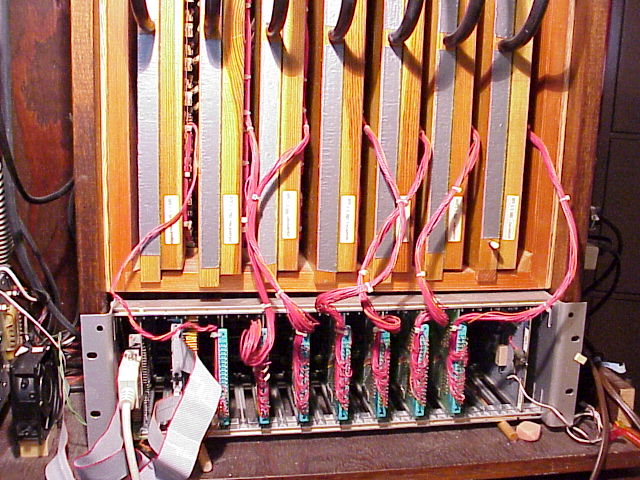

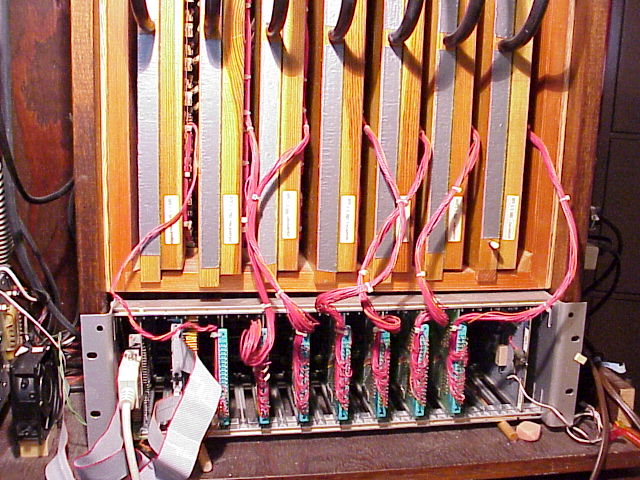

Figure 8. Back of Reader. The wooden contact blocks at the top

were the very first part of the whole project to be built. Vacuum

is supplied to each block through a manifold at the top. Tubes from

the tracker bar enter the front side of the blocks. Red wires from

the contacts are routed down the back to the electronic boards. A

small single board computer at the left generates scanning signals to read

the state of the contacts. If a change of state is detected,

the computer generates an ON or OFF event code for the appropriate channel.

These events are queued in the computer until they can be sent to the reader

program in the control computer, which eventually writes the output file

on disk. |

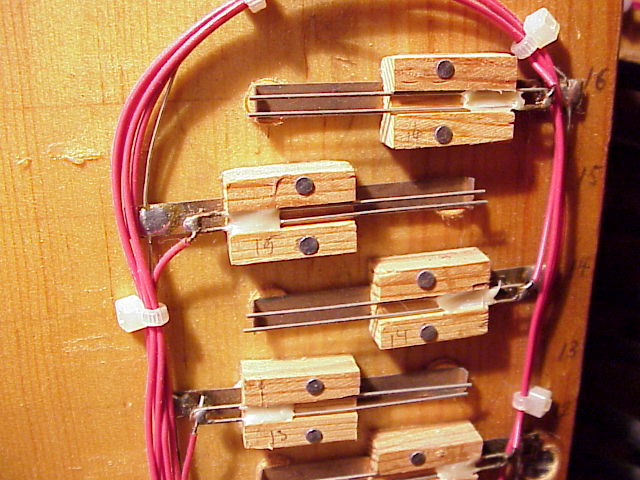

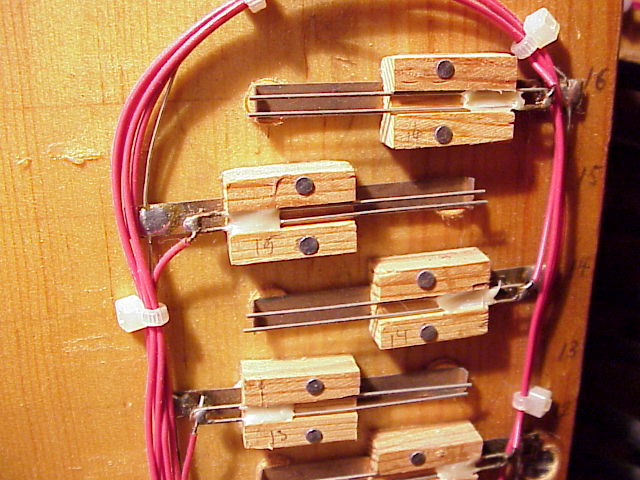

Figure 9. Close-up of reader contacts. Each tube from the tracker

bar is connected to a one inch diameter pouch in the lower part of the

block. The pouch pushes up on a 1/8 inch wooden dowel which slides

up through a brass tube in the top block. A 1/4 inch leather disk

is glued to the top of the dowel on the outside. The contact assemblies

are mounted on the outside of the pouch boards where the wooden dowel pushes

the lower contact up against the upper one. The contacts can be cleaned

and adjusted as needed. The lower contact is 3/16 inch phosphor bronze.

It provides the restoring force to the pouch. The upper contact is

a U shaped piece of silver wire. When the contacts are closed, the

lower part and the upper part have a different radius. This provides

a scraping motion at the point of contact, which helps keep them clean.

The contacts are operated at 21 volts DC. |

18 May 1999, 6 November 2002

|

Gallery

Gallery

Pictures

Pictures

tonnesen

tonnesen