Chapter 2.3 - Replacing the Stop Chest Self Energizing Gaskets

One of the unique features of later model Orchestrelle, discussed several times on MMD, was the special gasket used to join the stop chests and the rank chests. Since the many structural interfaces within the organ precluded these surfaces from being tightly drawn together, this gap was made deliberately large. The rank chests just slide easily in between the two stop chests. To seal the connection, a self energizing gasket was devised. This was a large square of soft leather, glued down only at its edges. Wind trapped under this piece inflated the leather, causing it to seal to the mating surface.

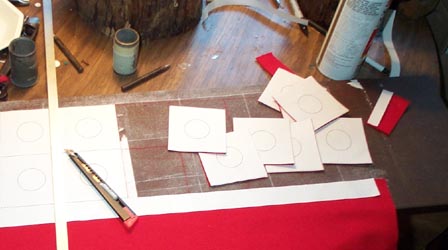

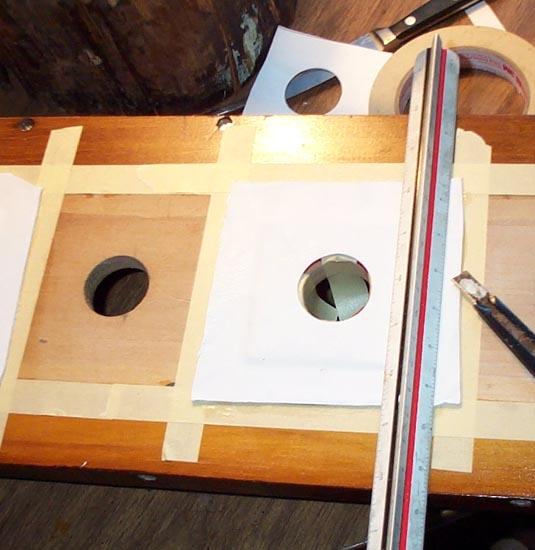

The new gasket should not be stretches tight, but rather be loose and able to "lift" in the center, rather like a pouch in reverse. I don't know how Aeolian achieved this, but I decided to make a felt form, to hold up the center part of the leather during gluing. Using the "sticky board", a piece of Masonite made tacky with 3M "Spray-Mount' frisket adhesive, lay down a piece of felt for cutting. Make a pattern on a graphics program (I use Visio), print it, and make it tacky also with Spray Mount. Stick the page to the felt, and use it to cut out and punch the felt form. I will use this technique for al \l the repetitive felt and leather pieces in the project.

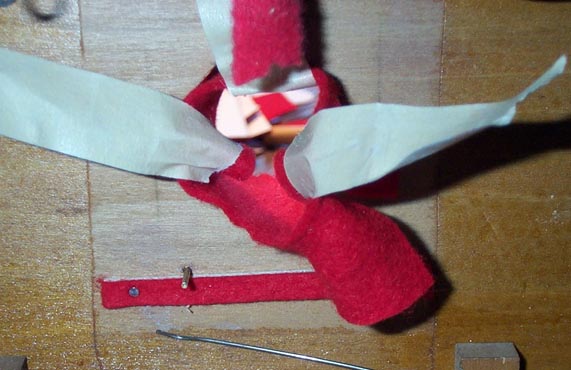

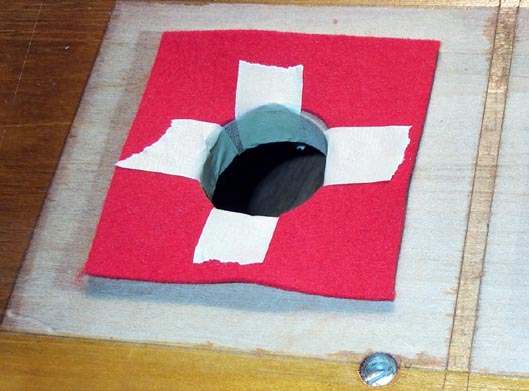

Stick the felt form to the center of the gasket area with masking tape through the central hole.

Likewise make the leather blanks. I used Valve Cambretta from The Leather Supply House, which seemed to match the original material. Make them oversize, since the existing gluing square must have originally been done by eye, and the holes are not exactly in the center. The round log in the background is a Durrell Armstrong "Kansas Hedgewood (boxwood) punching block". Handiest thing in the world, and really works better than any modern material for punching. I wish he still sold them; mine is still good after 36 years.

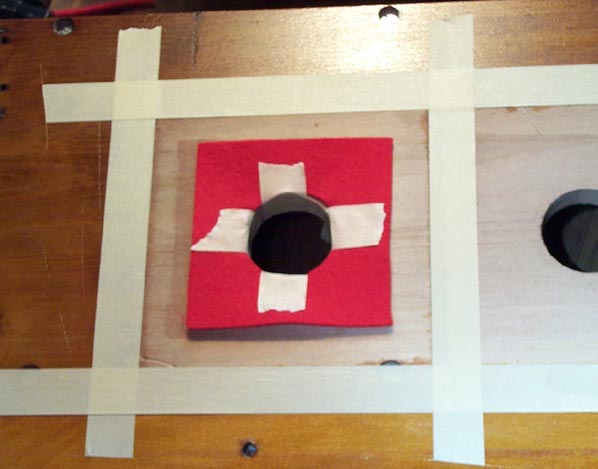

Now mask the outer edges of the gluing square. Using a small brush, run a line of hot glue about 1/2" to 5/8" wide all around the square, and stick on the leather. Press it down all around the rim; the felt square will hold the middle in the "inflated' position.

When the glue is set, trim the piece using the inside edges of the masking tape as a guide. Then peel off the tape, along with the excess glue and leather. As you see, one has to do every other one, the go back and do the remaining ones, to allow room for the masking tape.

Lastly, go inside the box; grasp the masking tape that held the felt form in place, and pluck out the whole thing, leaving only the leather, loosely covering the inflatable part of the seal.