Chapter 2.5 - Releathering the Stop Action Pallets

The pallets which cover the openings between the stop chests and the rank chests are covered with a thick layer of fine-grained, soft white felt, and dense, thick kidskin. I selected Organ Supply Industries #6101.03, 9/64" fine white pallet felt, and Leather Supply House medium goat, as the best match for the original.

It is important that the felt-leather layer be thicker than the heel rest pad, 1/8", so that the pallet rests firmly on the valve seating surface when closed. The rear end of the pallet rests on this only when open, so that the pallet seating surface is then not touching anything. Otherwise the rear edge of the leather seat will be squashed into an angular shape, and its seating surface flatness would become distorted.

To clean the pallet, just pull off the old felt, and wash the excess glue off the pallet surface with a damp rag. It would be wrong to use the belt sander, since one could never make the surface as flat as it was originally. One thing that Aeolian always did was to use the best seasoned and quarter-sawn wood throughout their products. Everything I have found so far is still as flat and square as could be made.

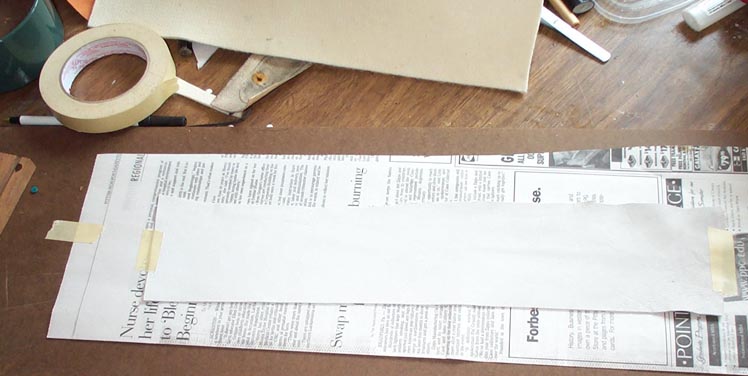

First cut a piece of leather larger than the total requirement, and tape it face down on a piece of newspaper.

Then cut a piece of felt about the same size. Using hot glue and a 2" paintbrush, apply glue to the back side of the leather, and stick on the felt.

After the glue is set, determines the correct length of the finished seat;

and cut the piece to that length.

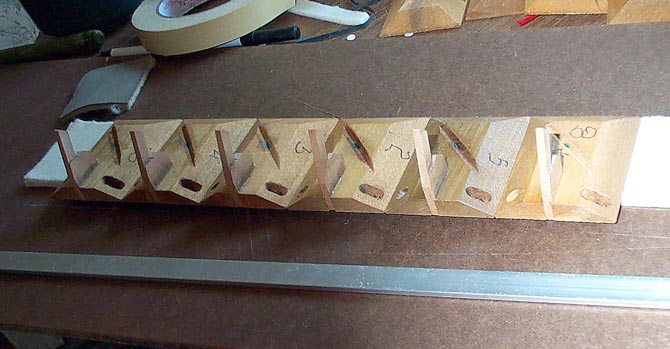

Using hot glue, set the pallets carefully on the strip. They should be touching, edge to edge.

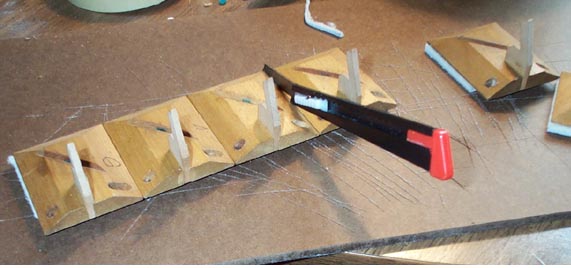

When that joint has set, cut the pallets apart. Use a fresh "snap" on the knife, and hold the knife as vertically as possible, to keep the edges of the cut square.

People will ask "Why use hot glue instead of some modern valve cement to join the leather to the felt? Won't it get stiff when it hardens?" The answer is; first of all, that is what the original builder used for all his flexible, composite joints. Second, hot glue is still the best for this because of its unique properties. Hot glue will not migrate into any porous substance very far beyond the mating surface. If any of the glue in its hot, liquid phase, tries to soak into anything, that bit is separated from the thermal mass of the glue layer, cools down and jells, and can no longer soak into anything. When the glue dries to its final "glass" phase, it becomes brittle. The first time the material is flexed, this layer breaks up into millions of tiny individual crystals; each one keeping a grip on the individual fibers that it is near. But the total joint becomes as flexible as if the glue wasn't there. Modern polymer adhesives remain liquid until they fully dry, and can soak into porous substances and stiffen them. This adhesive layer remains as a rubbery mass inside the joint, and will never flex as well as a hot glue joint.