Chapter 8.3 - Assembling and Testing The Tempo Regulator

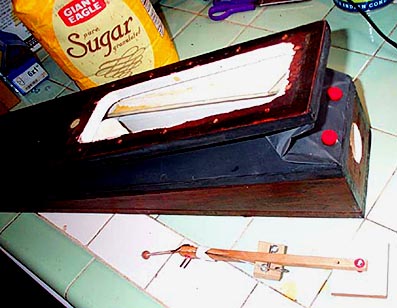

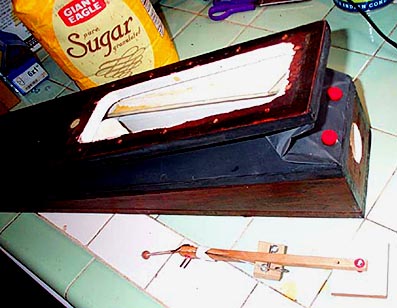

Here are all the internal parts ready to install. The pallet is covered with medium white felt and medium goatskin, just like all the stop pallets. .The pallet was made out of a mahogany scrap, so the top surface was covered with paper, apparently to plug the leaks in that porous wood. The pallet was originally free to turn on its screw. but with the new inside mounting screws, it might hit the screw heads. I added a pallet guide pin to keep it square with the lever. Note the little piece of vellum glued to the lever to keep the spring from popping out of its groove; a nice touch in the original which I replicated. The tension hook hole in the lever was rebushed, and a new hook was made; the old one made of steel had rusted through around the leather nut. A goatskin punching will be glued around the hook hole in the lid, so the leather nut will seal when the hook is under tension.

By "screwing" the nut-plate forward or back along the length of the spring, the number of active coils can be changed, thus making the spring rate higher or lower. By holding the nut-plate from turning, and screwing the long machine screw in or out, the tension at any given deflection can be adjusted. I tried various commercial springs, but ended up winding my own with #14 piano wire around a 1/4" dowel, resulting in a spring about 3/8" in diameter. For a pressure setting of 1.8" WC. (a bit lower than the playing pressure of about 2.25 " WC) each spring only has to have a force of about 1.7 pounds. By trying various combinations of number of coils and length on the bench, I got a preliminary setting combination that worked.

Then the whole thing was put in the organ, and final adjustments were made, using the rebuilt motor (see chapter 9) temporarily connected with a piece of organ tubing. Soon the motor was turning smoothly and steadily, regardless of how hard I pumped the organ.

As Kevin McElhone has noted, the roll motor takes a lot of the pumping effort; at the low pressures in the Orchestrelle, the motor pneumatic area (and volume) have to be far larger than on a piano. Calculating from the transmission gears and chains, the motor turns 158 RPM at tempo 100 (The highest on the scale), and 31 half strokes on the pedals are required for that speed. Luckily most 58 note rolls call for tempos from 30 to 60. The slowest I could get the motor to turn smoothly was about 6-1/2 RPM, tempo 4. Not a practical speed, but it must be noted that a few organ rolls, unlike piano rolls, call for occasional very low temps, as low as 15, so the low end of the scale has to be allowed for.

That is the last component "below the deck". Now the instrument was cleaned up and mover from my garage to its permanent home in the dining room, just in time for the cold weather.