Chapter 19.5 - Preparing the Rank Pouches

First, the old link wire staples are pulled out of each pouch follower. Then the old remnants of leather are pulled off.

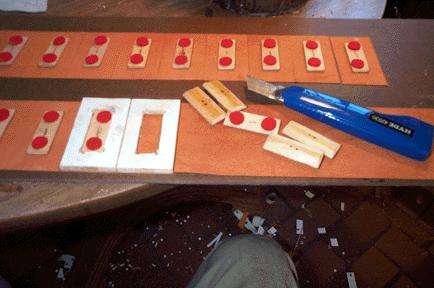

All the pouches, small and large, have the same size wooden follower, with two 3/8" felt "bottoming pads". The pads used near the bass ends of the ranks, are softer and very slightly thinner 9/64" white felt. The treble pads are firmer 3/16" red felt.

The leather is not glued all across the top of the follower, but just in a narrow band at the peak of the rounded contour of the wood. To remove the bits of leather and glue left on the follower, without soaking the whole piece and loosening the pads, the followers are laid, glue side down, on a wet towel. After a few minutes, the glue softened, and can be rubbed off with the finger.

A correct match for the old material is Leather Supply House item GTX, .008"-.010" X-Thin Tan Pneumatic pouch leather. It is important to get the follower accurately located in the center of the pouch. That makes sure the follower is in the center of the pouch well, since the pouch is centered over the well by eye, using the edges, tops and bottoms of the pouch as a guide. To center the follower correctly, and to make the rectangle of leather easier to cut, 1/4" plywood templates were made, with holes in the center that just fit the follower. The templates for the longer base pouches are 1-3/4" wide by 3-5/16" long; the treble templates are 1-3/4" wide by 3-1/8" long. The opening is 23/32" wide by 1-7/8" long.

A clean piece of Masonite is made slightly sticky with Spraymount. The hide is laid flat on this, shiny side down, and is cut into strips as wide as the pouches are long. A template is put on the strip. The rounded side of the follower is spread with hot glue using a finger, along the "ridge line", and the follower is then pushed downward through the hole. The pouch is cut to width along the long edge of the template, and a second template is laid down along side the first one. Bu the time the second pouch is glued and trimmed, the first follower has gelled tightly to its pouch. Then the first template can be pulled off and set down farther along the strip. By thus leapfrogging the two templates along the strip, all the pouches are fairly quickly made. 270 small pouches and 78 big ones are required. This took six whole pouch skins; luckily I have more money than sense in my old age.

The old staple holes are located through the new leather using a strong light and an awl, and these holes are pricked through the leather. The new staples, with the leather tab already attached, are pushed through the holes. See the next chapter about the staples.

The follower is too thin to get a good grip on the staple just by friction. The original machine made staples had tack-pointed ends. When they were driven by machine (the old pouches showed the mark from the stapler head), the pointed ends were bent back by the stapler anvil, and the staple was "cinched" firmly.

I could make such pointed staples, so I firmly fixed the staple another way. The new staples were pushed all the way through the holes, so their tips poked out just a little bit. Using a drop of thick shellac, the staple was "glued" into place. Shellac is the only adhesive that I know of, that adheres equally to wood and metal. This procedure also seals any leak where the staple was pushed through the old holes.

Finally, the pouch end of the link wire was twisted on. Luckily I had a bunch of old #26 pipe organ cable. This was done now instead of after the pouches were laid, for two reasons. First, it is a lot easier to twist the pouch assembly and hold the loop of wire, than the other way around. Also, the space between the upper layer of pouch cups is so narrow, that it would be hard to reach the lower row of staples.

After the wire is twisted tight, the loop in the wire is pushed gently towards the pouch. This causes the loop to get slightly wider, and looser. The loop must be loose enough to swing freely, but not so big as to slip out from between the ears of the leather tab.