Chapter 27 - Final Revision and Adjustment of the Primary Valves

After I got the organ to play rolls properly in the mounted spool box; I discovered that the performance was not up to standard. Some notes missed occasionally, and many fast trills would not play at all. I became obvious that my initial assembly and adjustment of the primary (see Chapter 17) was inadequate. Testing by attaching a good primary valve to all the secondaries proved that the secondary valves and the pulldown pouches in the chests were all OK. So I had just been too eager to complete the primary; and had not used sufficient care. Shame on me.

The first thing I noticed was that the small pouches were not deep enough to develop the proper toriodal shape needed to maximize their force on the stems. See Johan Liljencrants' article in the MMD Technical Archive for the theoretical development of this concept. So I had to replace the pouches with ones dipped slightly deeper. When the new pouches were dry, the edges were carefully rubbed around with the finger, to break up any glue drawn in by the dipping, so the pouch had full flexibility all the way to the edge of the pouch well.

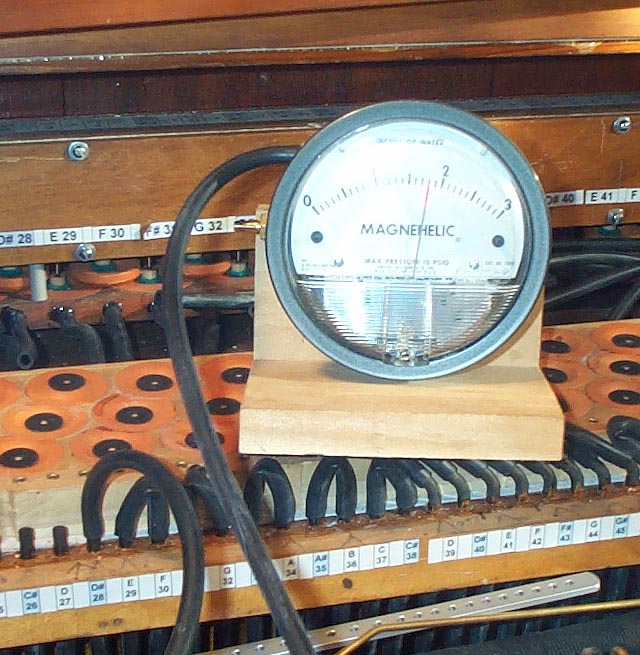

Then, I devised a test to make sure they worked correctly with their associated bleeds, and had no other significant leaks in the circuit. I took a tube from the organ wind, with an aprox. 1/32" bleed restriction in the tube. This restriction very approximately replaced the restriction imposed in the pouch wind from the pressurized spoolbox, through the roll perforation and the tracker bar port. This tube was connected to the pouch, with a gauge teed into the tube downstream of the restriction.

First the gage was read with the playing bleed open. Normal readings proved to be between 1.6 and 1.8 inWC. A lower reading here would indicate a leak in the pouch or somewhere else in the circuit. At first a number of such leaks were found at one end of the rail. It was discovered that there was an irregularity in the gasket surface where the nipple manifold was joined to the pouch board. When this was fixed, there were no more low readings, showing that all the pouches were reasonably leak tight.

A higher than normal reading meant that there was not enough flow through the bleed. This happened several times, and was found to be due to some glue or shellac in the bleed. When this was reamed out, all the pouches tested out within limits.

Then the playing bleed was covered with my finger. Now, with very little flow through the test restriction, the pressure rose to within 1/10th of an inch of the chest supply pressure. Any lower reading here would have indicated some leakage flow, apart from the small amount that seeps through the leather.

It is important to note that there is no particular significance in the exact size of the restriction in the test tube, as long as it is bigger than the playing bleed. The restriction in the test tube is in series with the restriction of the playing bleed, and the leather seepage in parallel to it. With two restrictions in series on the same flow, the pressure drop across each is approximately inversely proportional to the area of each. and the total pressure drop is that between the chest and atmosphere; 2.5 inWC in this case. Since the test restriction is the same for each test, it follows that all the playing bleeds are also very close together in capacity, as long as the test restriction pressure drop (1.6 to 1.8 inWC) and the bleed pressure drop (0.6 to 0.8 inWC) are within the same proportional range.

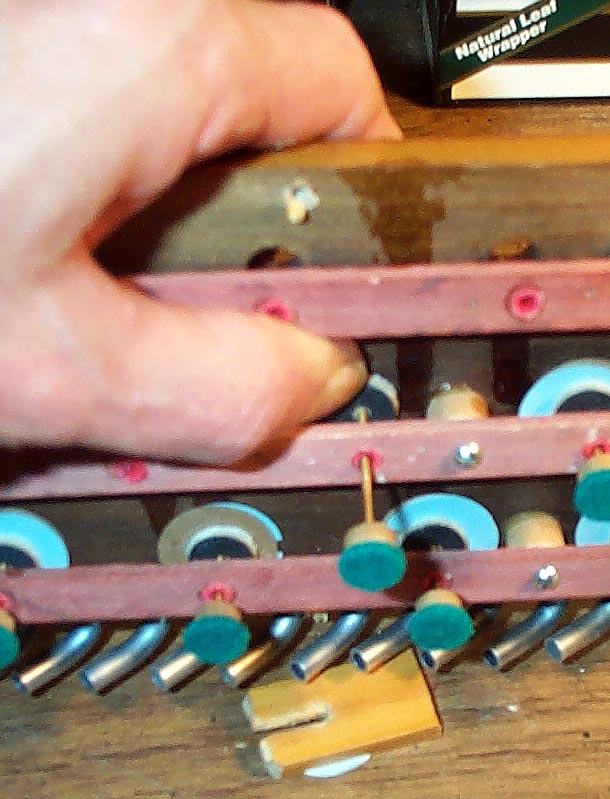

Also, I discovered that the valve disks I had made before had become loose on the stemwire threads. Original, I had copied the originals, and made the valve seat composite out of seat kidskin and canvas. Apparently the canvas originally used by Aeolian was denser that the kind I had used. So I made new valve disks from a composite of kidskin for a good seal, and cowhide packing leather for a good grip on the screw threads. Spacers were made so that the screwed together valve assemblies ended up with the same dip and gap.

In order to perform the final functional test, some special tools were fabricated. In order to test each valve, the wind box must be installed over the valve board. To avoid having to repeatedly using the 18 screws that hold the box in place, three clamps were made. These allowed me to quickly open or close the wind box, during the testing and final adjustment of each valve.

To test the sensitivity and speed of response of each note, an oscillator was made, to produce a very fast trill, or series of pneumatic pulses.

A Schaff pin vice was used to grab the top of the valve stem, so that it could be turned, to adjust the position of the valve disk on the stem. The handle of the pin vice was cut off, until its weight was such that the normal pneumatic force from the pouch would lift it easily. The extra weight of the vice insured that the valve would work correctly against the downward force of the wind when the box was installed and pressurized.

Each valve was adjusted as shown below. By operating the oscillator, one can watch the valves rapidly open and close.

After the initial adjustment, the box was clamped on, and pressurized. Now for the real test. When the oscillator was operated, the actual note in the organ usually sounded the trill; about 8 - 10 Hz, far faster than any real world trill on a music roll. What surprised me most, was that the entire note producing system, would respond at this speed. The relatively massive secondary valves; the large volume of the channels leading from the secondaries to the reed pallet pouches; and the six big pallet pouches and large pallets themselves connected to each note, all seemed incapability of such rapid switching back and forth between their two states. Of course the bigger 8' and 16' reeds at the bass end simply can't begin to speak that fast, even though one can hear the pallets snapping open and shut at the test speed. But by puling a 4' flute, one can hear the resultant musical trill all across the scale.

Of course, all the 58 note would not trill properly, so the box had to come off, and further adjustment done. By trial and error, I finally figured out a diagnostic approach, and the appropriate adjustment. Once this approach was discovered, the remaining notes were cleared up fairly quickly.

In some cases a note sounded when the oscillator was stopped with a hole uncovered (they all did this), but the trill was weak or nonexistent when the oscillator bar was pulled rapidly. This meant that the valve was 'too high' in the pouch, or the gap was too small. Screwing the valve down or opening the gap, just a bit, cured this.

On the other hand, some notes sounded more or less continuously as the oscillator was pulled, with little or no silence during the 'off' parts of the trill. This means that the valve is too far down in the pouch well, or the gap was too big. Again, the appropriate adjustment fixed all such notes.

After all the notes responded correctly when repeatedly tested with the oscillator, the box was finally screwed on, and the spoolbox was retubed and installed. Then the organ was tested with the test roll. All the trills on the test roll (much slower than the oscillator trills) sounded cleanly even at 'reroll' tempo (about 115). Except for one note, which would not speak!. I said "Oh, .....! I have to take everything apart again to fix that". Just in hope, I pulled the tube from the tracker bar, and tested it with a mouth tube. There was very little flow. It turned out that the tube leading down from the tracker bar to the manifold had become pinched in the rear, when the spool box was folded up into its final position. Whew! That was fixed right away, and everything played perfectly from then on.

Lesson learned, yet again: "Work as carefully as you can the first time; otherwise you have to go and do it all over again."