| You Are Not Logged In | Login/Get New Account |

|

Please Log In. Accounts are free!

Logged In users are granted additional features including a more current version of the Archives and a simplified process for submitting articles. |

|

MMD

Gallery

Gallery

Pictures

Pictures

jphillips1

jphillips1

|

|

by John Phillips (961218 MMDigest)

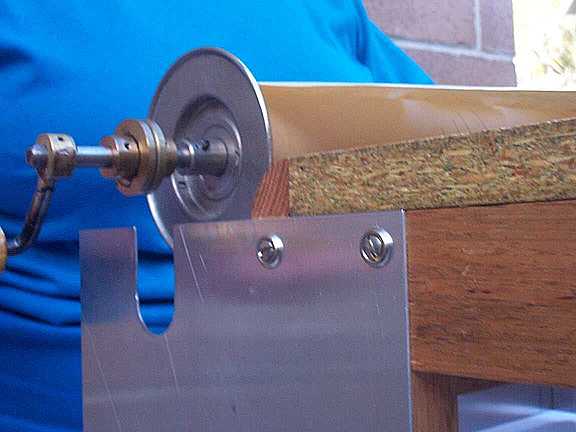

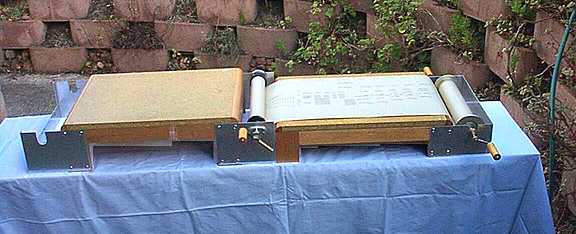

Yesterday I finished a project I've been thinking about for years and have been actually doing something about for several months. It's a table for repairing 88n piano rolls. It looks like a little wooden coffee table about 18" (45 cm) long with legs about 5" (12 cm) high. It's a few cm wider than a piano roll and has a flat chipboard top with rounded ends. There is a sheet metal housing screwed to each end of the table. One end contains the spring loaded chuck and the drive chuck for a roll. These were salvaged from a discarded spoolbox found on our local garbage tip by a friend. (His find provided the impetus to get this project going.) The housing at the other end contains the take-up spool from the same spoolbox. Crank handles on the drive chuck shaft and the central shaft of the take-up spool enable the roll under repair to be moved back and forth. So far this sounds like any old repair rig but wait, folks, there's

more!

Often, when repairing a roll, one comes across a section where some (supply your own adjective here) person has applied sticky tape to the underside of the paper, or where the paper is so badly folded and torn that access to the underside is necessary. This outfit makes that possible; so far I've only described half of it. The bearings for the shaft of the take-up spool are two brass disks, about an inch in diameter and a quarter of an inch thick. The shaft fits through holes drilled in the centres of the disks. Each disk has a shallow trough turned in the middle of its rim. The sheet metal housing at the take-up end has two vertical U-shaped

cutouts, into which the brass disks' shallow troughs just fit. This

means that the take-up spool can be lifted up out of the housing at any

time. When I want to get at the underside of a roll I clip a second "coffee

table" with shorter legs to the music roll end of the first table.

This second table has a metal housing with U-shaped slots at its far end.

All I have to do is lift the take-up spool out of its usual position, move

it up and over in a wide arc and fit it into the second set of cutouts.

Hey presto! The roll is now lying underside up on the second table

surface.

Why does the second table have shorter legs than the first? Because

the paper is now unwinding from the bottom of the roll rather than the

top.

Merry Christmas, everybody. John Phillips

12 July 2000 |

|

|

|

|

|

|

|

|

|

CONTACT FORM: Click HERE to write to the editor, or to post a message about Mechanical Musical Instruments to the MMD Unless otherwise noted, all opinions are those of the individual authors and may not represent those of the editors. Compilation copyright 1995-2026 by Jody Kravitz. Please read our Republication Policy before copying information from or creating links to this web site. Click HERE to contact the webmaster regarding problems with the website. |

|

|

||||||

|